Inventory is an important foundation for companies that provide or produce goods. Good inventory management can help a business grow and succeed.

There are many advantages to implementing proper inventory management. These benefits include reducing costs, increasing cash flow, and ensuring a smooth production process to meet product demand.

Of course, managing inventory is not free from various obstacles. However, the most important thing is how the company can overcome this problem. With the right solution, companies can increase profits while providing the best service to consumers. Here are common issues in inventory management and ways to overcome them.

Building a Solid Foundation for Progress and Profit

Inventory is a vital element for companies engaged in manufacturing and distributing goods. An effective inventory management system is the main key that opens the way to business development and success. Its proper implementation can produce various benefits, such as reduced costs, increased cash flow, and smooth production processes to meet market demand.

However, in the journey of managing inventory, obstacles often arise. These challenges can hinder efficiency, trigger waste, and even harm a company's profitability. The key lies in how companies find effective solutions to overcome them. With the right strategy, companies can maximize profits and provide the best service to customers.

Getting to the Root of the Problem: Common Challenges in Inventory Management

Based on experience and observations, some common challenges often faced in inventory management are:

1. Inefficient Inventory Management Process

- Symptom: Manual, labor-intensive, and outdated systems are still in use, hampering business agility and scalability.

- Impact: Processes become slow and error-prone, resulting in delivery delays, customer dissatisfaction, and potential data loss.

- Solution: Implement an integrated inventory management system that leverages cutting-edge technology. These systems can automate manual tasks, improve data accuracy, and provide real-time insights for faster decision-making.

2. Accumulation of old, unsold goods

- Symptom: Obsolete goods pile up in warehouses, taking up valuable storage space and tying up capital that could be used for other purposes.

- Impact: Storage costs increase, profitability decreases, and the company's image is tarnished due to inventory that is not relevant to market demand.

- Solution: Apply the First In, First Out (FIFO) method to ensure optimal stock turnover. Use an expiration date tracking system and conduct sales data analysis to identify slow-moving products and consider discontinuing them.

3. Lack of Inventory Visibility

-

Symptoms: Difficulty tracking the location and stock status of goods, thus hampering the process of order fulfillment, delivery, and returns.

-

Impact: Delivery delays, out-of-stock, delivery errors, and customer dissatisfaction increase.

-

Solution: Use a real-time inventory tracking system that integrates with barcodes, RFID, or other IoT technology. This system allows accurate monitoring of stock movements and conditions, making it easier to identify available goods and their storage locations.

4. Advantages of Stock Goods

- Symptom: Capital is tied up in excess inventory, triggering wasted storage costs, insurance, and potential stock damage.

- Impact: Cash flow stagnates, profitability decreases, and storage space is wasted.

-

Solution: Optimize demand predictions by using historical sales data, market trends, and external factor analysis. Implement a Just-In-Time (JIT) system to order goods only when needed, thereby minimizing excess stock and increasing capital efficiency.

5. Unexpected Market Demand Fluctuations

-

Symptoms: Difficulty anticipating dynamic changes in demand, risk of running out of stock or overstock.

-

Impact: Inability to meet customer demand, lost sales, and waste of capital due to excess stock.

-

Solution: Analyze sales data regularly and implement a dynamic demand prediction strategy. Leverage artificial intelligence (AI) and machine learning to identify demand patterns and predict market trends more accurately.

Towards a New Era: The Right Solution for Effective Inventory Management

With advances in technology and the presence of various innovative solutions, companies can optimize inventory management and reach the pinnacle of success. Here are some strategic steps that can be taken:

- System and IoT Adoption: Implement an integrated inventory management system with IoT technology to make it easier to track stock, monitor the condition of goods, and automate the management process.

- Efficient Stock Control: Utilize an inventory management system to monitor the location and condition of stock in real-time, so that storage of old goods can be reduced and turnover

- Real-time inventory management system, having a stock management system with real-time data updates has various benefits for companies. Starting from tracking the location of stock items and the amount of stock stored in the warehouse accurately. This will certainly increase demand fulfillment and consumer satisfaction.

- Regular stock taking, and scheduling periodic stock taking can overcome inventory management problems. With a regular schedule, it will be easier for companies to track the stock of goods stored in the warehouse in detail. Apart from that, periodic stock-taking can also increase inventory management efficiency, reduce costs, and increase timeliness and profits.

- Complete Inventory Management System data, having data related to stock management, will make it easier for companies to find out procurement needs and understand consumer needs. With complete data, companies can carry out data analysis and prepare predictions for inventory management needs. That way, management can run efficiently and the company will be able to meet the ever-changing needs of consumers.

Overcome stock management problems using Odoo.

In this digital era, agility and efficiency are the main keys for companies to develop and compete. This also applies to the inventory management aspect, where companies are required to manage inventory appropriately and accurately to avoid various obstacles that can hinder progress.

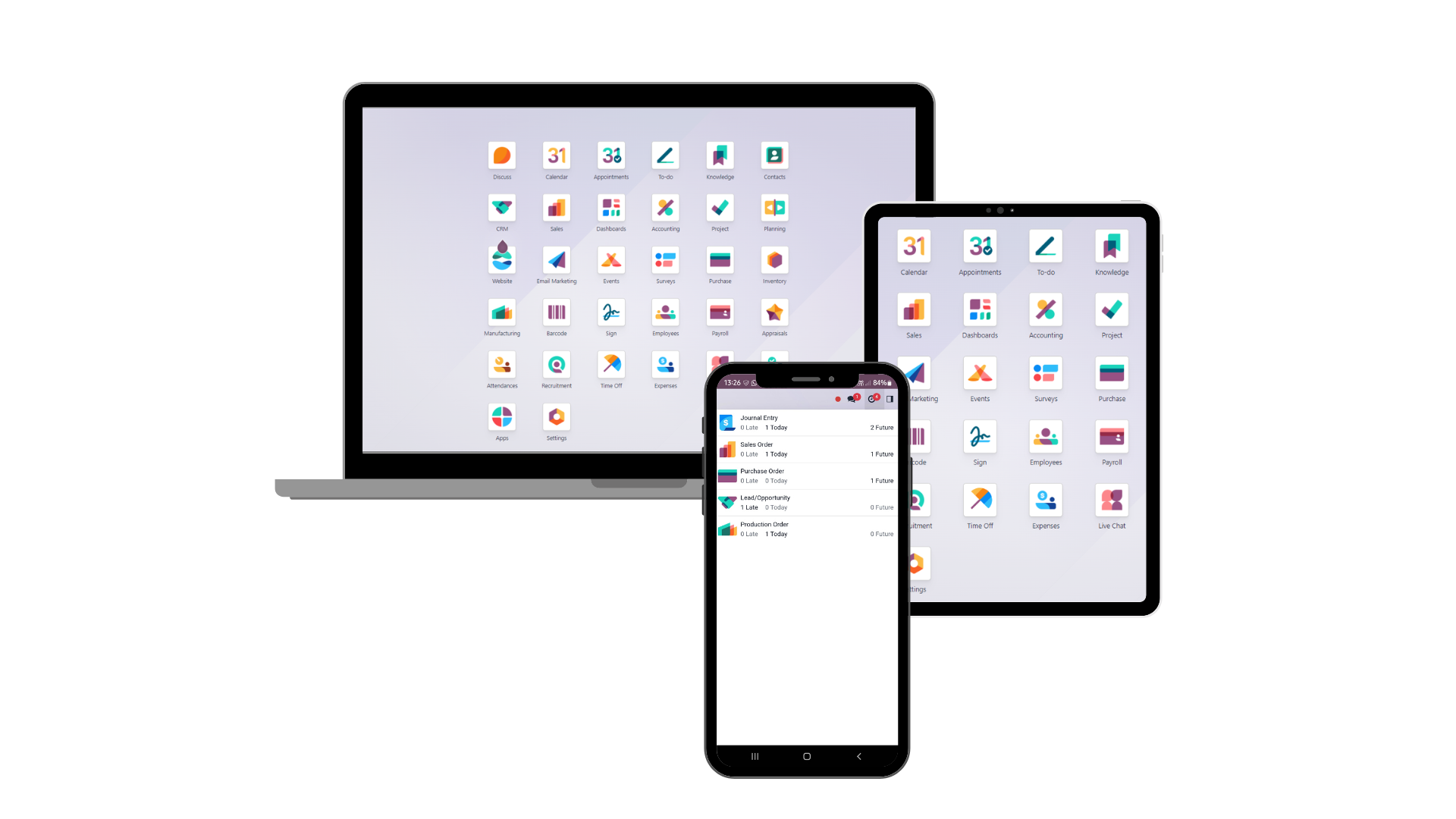

Odoo, as a comprehensive Enterprise Resource Planning (ERP) platform, comes with innovative solutions to help companies overcome various problems in stock management. With Odoo, you can optimize inventory processes, increase stock visibility, and maximize business profitability.

Conclusion: Odoo is a Reliable Partner in Inventory Management Transformation

By adopting Odoo as your inventory management solution, you can:

- Improve inventory process efficiency and accuracy

- Reduce storage costs and waste

- Improve stock visibility and control

- Meet customer demands better

- Increase profitability and business competitiveness

Odoo has been trusted by millions of companies around the world to optimize their business processes. With a user-friendly interface and high scalability, Odoo can be adapted to the unique needs of each business.

Initial Steps Toward Inventory Transformation

If you're ready to take your inventory management to the next level, contact Odoo Indonesia today. Our team of experts is ready to help you choose the right solution and implement it successfully.

With Odoo, create a new era of efficient, effective, and profitable inventory management for your business.